%201.png)

Still using outdated VMS setups? It’s costing you more than you think

The longer you wait, the more you lose — in time, manpower, and carbon.

Risk of Not Switching – What You're Paying For

Manual battery swaps every 8–12 hours mean increased overtime and site visits.

Labour Costs

Downtime

Frequent shutdowns due to battery depletion — no alerts, no predictability.

Carbon Emissions

Frequent changes = unnecessary fuel and waste. Each trip adds to your carbon footprint.

Lead-acid systems degrade fast — more replacements, more disposal issues.

Short Lifespan

Ultrasonic Sensors

.png)

Water level Sensor

Monitor temperature records across multiple sites with our easy-to-use dashboard. Each project site is labeled for quick reference, displaying real-time temperature.

.png)

Automation Sensor

Monitor temperature records across multiple sites with our easy-to-use dashboard. Each project site is labeled for quick reference, displaying real-time temperature.

.png)

Water level Sensor

Monitor temperature records across multiple sites with our easy-to-use dashboard. Each project site is labeled for quick reference, displaying real-time temperature.

Dashboard

LGR's Unified Visual Dashboard provides real-time monitoring and control of the Automated ECM System. Designed for efficiency and precision, it offers supervisors a clear, data-driven interface to ensure optimal system performance. With the ability to consolidate multiple dashboards into a single platform, supervisors can seamlessly monitor all sites from one centralized location, ensuring streamlined management and quick decision-making.

Features

Water Level Sensor

Automatically starts the pump when water reaches 1200 mm and stops at 300 mm.

Dosing Sensors

Monitors two tanks (each 1000 mm). Automatically stops the pump and sends a Telegram notification if either sensor detects levels below 300 mm.

TSS Sensor

Continuously measures Total Suspended Solids (TSS). Automatically stops the pump if TSS exceeds 40 mg/L to prevent unwanted discharge.

Real-Time Monitoring

Tracks water levels, dosing levels, and TSS across all connected sites. Displays data through interactive graphs and sends immediate notifications via Telegram for critical events.

Alerts

WBGT send alert every hours in Telegram and Company & Site Notification.

Before

Before – The Operational Strain of Legacy Systems

Traditional VMS setups using lead-acid batteries demanded daily replacements, requiring manpower to manually swap out units and make multiple trips to the site.

This meant:

100% manpower allocation

80% trip frequency

60% battery change effort

It was labor-intensive, inefficient, and unsustainable — especially across large or remote sites.

After

After – Smarter, Cleaner Operations with LGR

With LGR’s integrated solar-charged lithium systems, we’ve drastically reduced the operational load:

70% less manpower

85% fewer site trips

90% reduction in battery changes

Our clean energy solution not only lowers costs and downtime — it streamlines your operations, enhances uptime, and eliminates the hidden drain of daily maintenance.

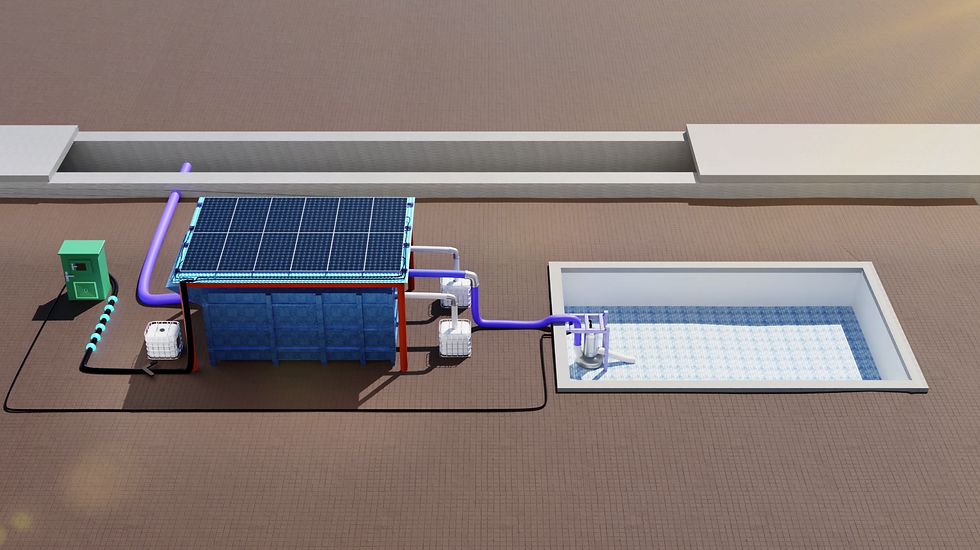

Beyond Batteries: The LGR-ATLAS Advantage

LGR-ATLAS isn’t just another power solution — it’s a complete shift in how site operations are powered, monitored, and maintained. While others still rely on outdated systems that drain manpower and fuel, LGR-ATLAS delivers a fully integrated, solar-hybrid platform designed for high-efficiency, low-touch operations.

With built-in load management, smart battery monitoring, and modular scalability, LGR-ATLAS turns clean energy into a strategic asset — cutting costs, reducing emissions, and proving compliance in one seamless package.

Where others offer batteries, we offer a smarter way to power your future.

.png)